Amirreza,

I would try three things.

One is to set the mass flow rate and inlet temperature to the

active layer as INPUTS to Type56 (they may already be set that

way) and then run some cases where you use a forcing function or

an equation to switch between a high inlet temperature and a low

inlet temperature and between flow on and flow off. If the flow

rate and inlet temperature are constant then sometimes it can be

hard to see what their effect is because everything is steady

state. In doing this, make sure that your weather conditions are

cold; if the building's ambient condition is close to 26C then

putting 26C water into the active layer is not going to have much

of a visible effect

The second thing I would recommend is to put a layer of

insulation on the side of the concrete that you are NOT trying to

condition with the active layer. We ran into this same situation

where there was a mezzanine that had a radiant floor. It was

impossible to control the temperature of the mezzanine area

without insulating the underside of that floor (which was also the

exposed ceiling below). It may be that a lot of your energy is

going up instead of down.

Lastly, instead of watching the air temperature, look at the surface temperature of the concrete. It should be quite close to the temperature of the active layer. That surface temperature should be more directly impacted by the active layer than the air temperature is

best,

David

Hello,

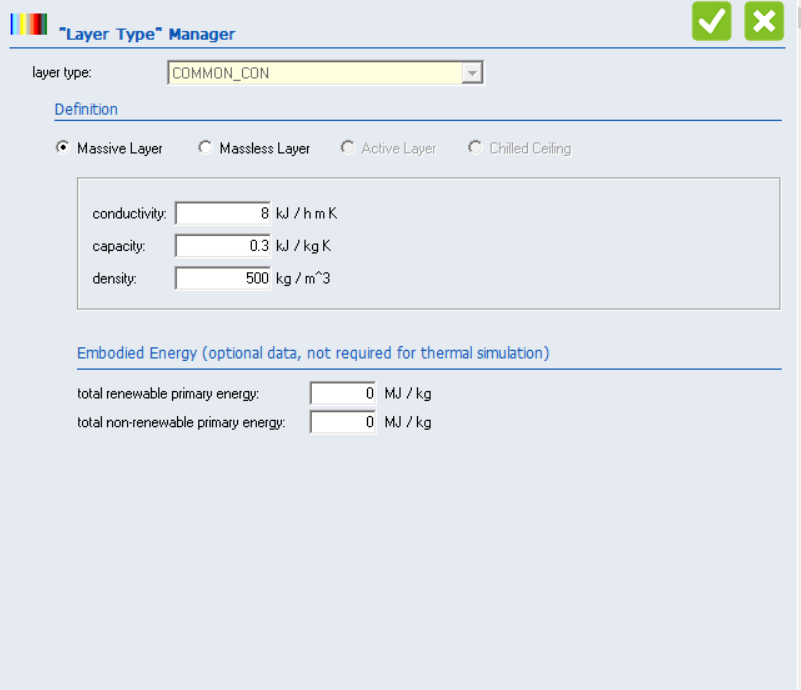

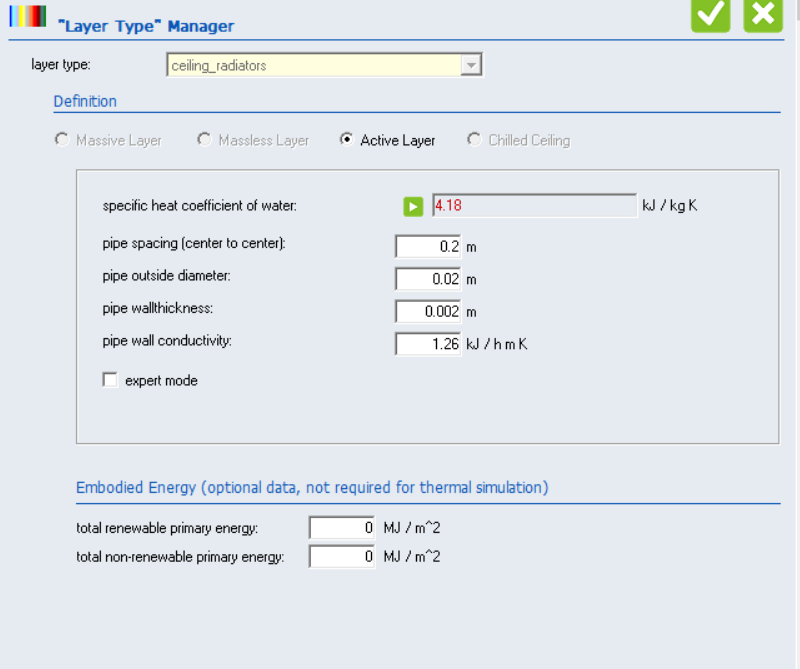

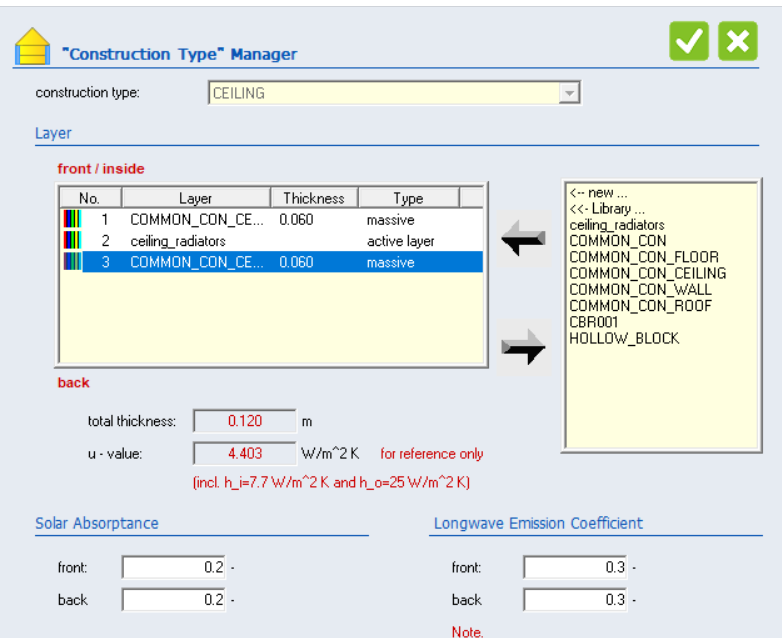

I am trying to model a ceiling heating system in type 56b. The actual heating system is actually some hot water heating panels that are located in the ceiling. The actual sizes or thickness of layers are not important, and I only expect the model to reflect a realistic behavior. To model the ceiling heating system, I putted an active layer between two layers of common concrete. The specifications of active layer, common concrete, and the ceiling structure are shown below. However, the model does not show a reasonable behavior because:

1- The temperature increment of the zone is very small (with 11000 L/H flowrate and 26 C inlet water for a 50 m2 zone)2- The temperature increment of zone does not change with the change of inlet flowrate3- When I change the specifications of active layer (for example by reducing the pipe spacing), the minimum required flowrate of water reaches to unreasonable high values

I tried to get a reasonable behavior by trying following actions:1- Reducing the thermal capacity of common cement: It did not work because when I have a big surface with very low thermal capacity, the solar radiation from windows increases the zone temperature to very high values (e.g. 30 C). The same happens with the use of low-capacitance layers like hollow brick.2- Trying the chilled ceiling: Although it is not exactly what I need, I tried it to see if it can have a reasonable behavior. But it does not do any change of indoor air temperature (maybe it is only coded for cooling!)3- Huge increase in inlet flowrate: Does not change anything !!!

I have attached the .b18 file as well. The inlet temperature and flow to the active layers are as inputs (from other components). The simulation timestep is 30 minuts. Would you please let me know why the zone temperature variation versus the inlet water temperature is extremely low and how I can fix it?

_______________________________________________ TRNSYS-users mailing list TRNSYS-users@lists.onebuilding.org http://lists.onebuilding.org/listinfo.cgi/trnsys-users-onebuilding.org

-- *************************** David BRADLEY Principal Thermal Energy System Specialists, LLC 3 North Pinckney Street - suite 202 Madison, WI 53703 USA P:+1.608.274.2577 d.bradley@tess-inc.com http://www.tess-inc.com http://www.trnsys.com