Dear Michael,

I cannot agree more that the use of optimisation must not be abused, by which I mean not to blindly trust the results it produces without a good understanding of the problem first. On the other hand, I have no problem recommending anyone, starters or experts, to pick up an optimisation tool straightaway as soon as the simulation model is ready. The tool can actually help you understand the design problem and/or pick out modeling issues. When unexpected results are given by optimisation, it is normally caused by errors in either the model, or the set up of the problem (e.g. the objective functions). Hence optimisation can be used as an effective way of experimenting with the model. It is a lot easier (and more enjoyable) than testing the model by hand. Once you have spotted a problem, like Ware did, you can then start drilling down into the model to find out why.

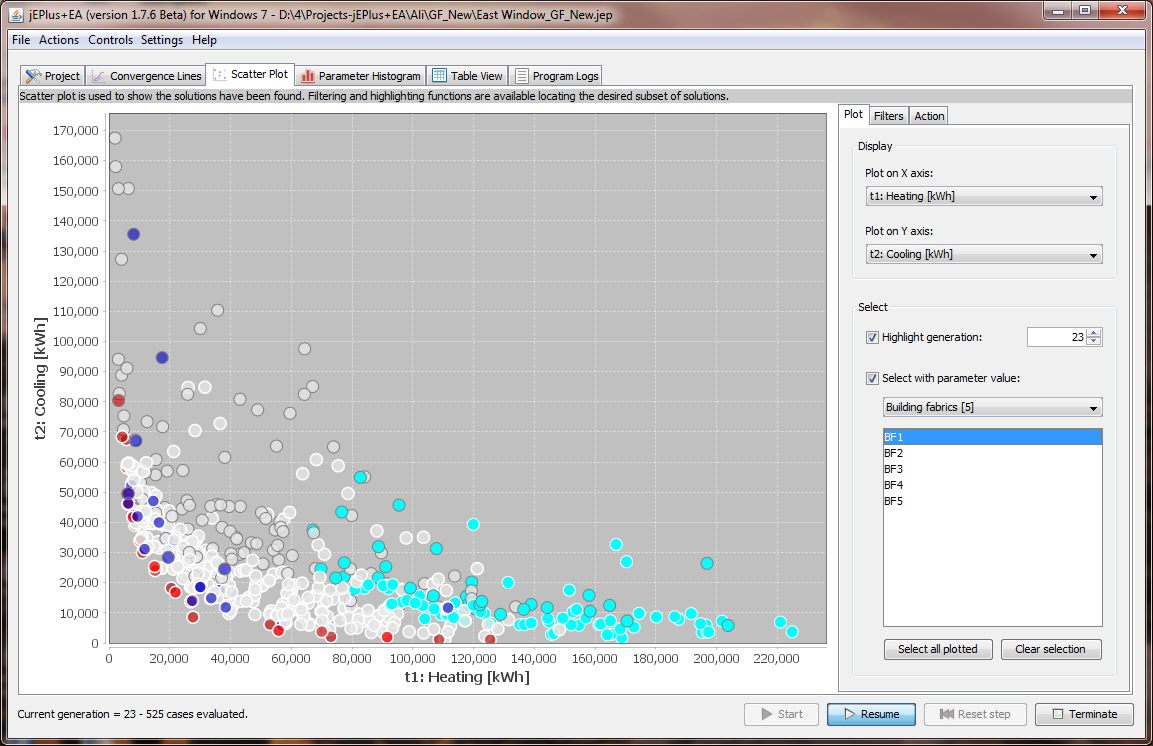

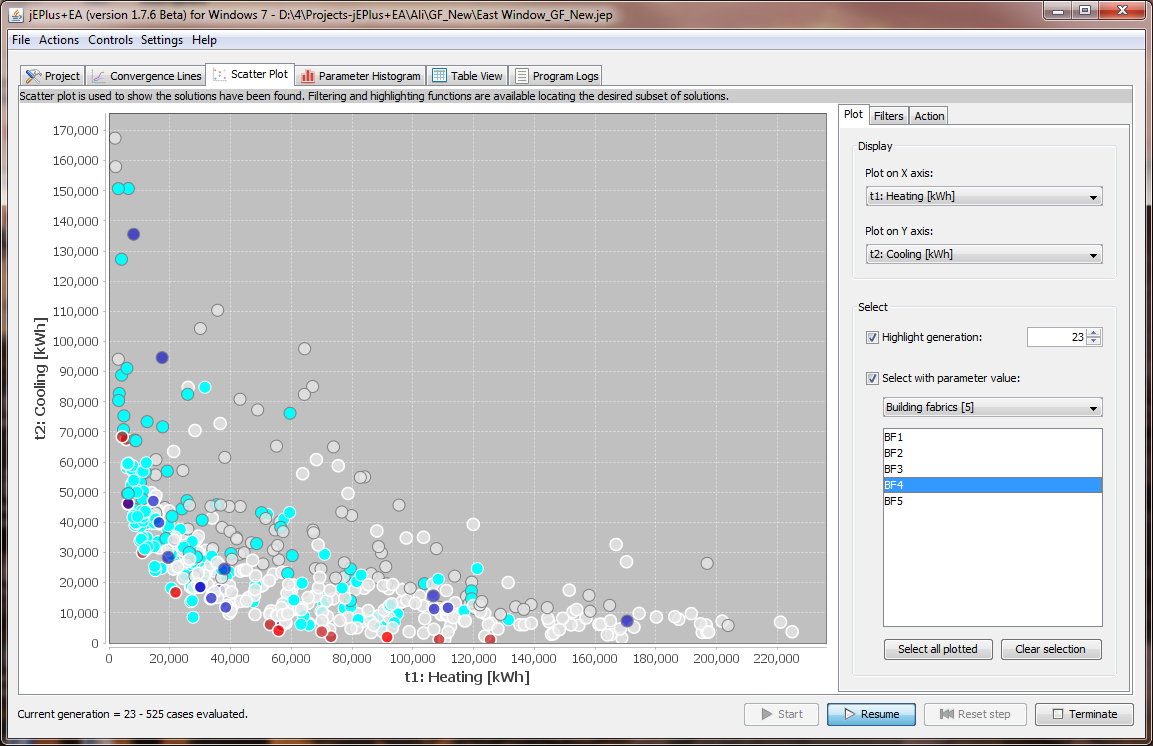

Back to the problem at hand, I think the life cycle cost is a valid objective if the projection of future utility rates can be adjusted to balance the initial cost and the savings from the renewable sources. "Finding me the most cost-effective solution that reaches a minimum solar fraction of..." is an excellent design objective. To realize it in optimisation you have to define minimum solar fraction as a constraint. I've got an impression that GenOpt can handle constraints, so this may be viable. However, a multi-objective approach is still preferable as it not only shows you the best solutions, but also the trade-off between the cost and the benefit, along with hints on the impact of each design variables. See the attached screenshots for an example...

Regards,

Yi

From: TRNSYS-users [mailto:trnsys-users-bounces@lists.onebuilding.org] On Behalf Of Michaël Kummert

Sent: 14 April 2016 21:55

To: 'TRNSYS users mailing list at OneBuilding.org'

Subject: Re: [TRNSYS-users] (PLEASE)optimization of a solar heating system combined with dual-source heatpump

Dear all,

For the design solutions “found” by optimization to be useful, the simulation must accurately represent the reality and the “cost” that was minimized must effectively represent the overall “performance” of a system. Trusting simulation requires to carefully look at detailed results in simple cases (not just yearly energy or “cost”).

I would therefore not encourage anyone, especially students, to “throw in all their design variables” into any optimization algorithm as soon as their simulation is ready. Jeff’s approach sounds very good to me, start with design parameters that make sense, check that your results and cost function makes sense, and explore (manually or through parametric runs) some design configurations. That way you will learn how the system is affected by its parameters and get a chance to check the plausibility of your results. I am willing to bet that, in the process, you will find some user errors, and possibly identify some bugs/limitations in the models you use. Then as a last step, you could indeed try a multi-objective, multi-parameter optimization, to check whether you might have missed some possible configurations.

Regarding the life cycle cost that always increases with solar collector area: in some (many?) contexts energy savings and renewable energy are in fact not economically viable without subsidies. So yes, it does happen that the “optimum” is not to have any solar collectors. In such cases it can be useful for the client to impose a minimum level of savings (or solar fraction) and formulate the design question as “find me the most cost-effective solution that reaches a minimum solar fraction of …”, rather than “find me the lowest cost design”. Another option is to express the cost of the useful renewable energy over the life cycle (levelized life cycle cost, in $/kWh for example). Again, manually exploring some design options will help you assess whether your cost function is appropriate.

And for those who have registered for the workshop on optimization with TRNSYS at the eSim conference, don’t worry… I will talk about optimization, but adding a grain of salt never hurts.

Michaël Kummert, Polytechnique Montréal

From: TRNSYS-users [mailto:trnsys-users-bounces@lists.onebuilding.org] On Behalf Of Dr Yi Zhang

Sent: Thursday, April 14, 2016 05:47

To: 'TRNSYS users mailing list at OneBuilding.org' <trnsys-users@lists.onebuilding.org>

Subject: Re: [TRNSYS-users] (PLEASE)optimization of a solar heating system combined with dual-source heatpump

Ware (?), as you can see, energy consumption and cost may be on very different scales. It is not logical to add them together to form an objective. If the cost numbers are much higher than the energy numbers, the combined objective will be dominated by the cost results, thus dictating the minimum collector area outcome. You have two options here, to use the life cycle cost alone as the objective (as the energy cost should have been factored in), or to switch to a multi-object approach.

Jeff, optimisation should not be that hard. I would suggest trying out jEPlus+EA or other GA-based tools. In most cases you can throw in all your design variables and let the algorithms do the hard work. The problem with the tiered search strategy is that you are likely to narrow down the results prematurely (i.e. within the ballpark) and miss solutions elsewhere. The magic with optimisation is that it can give good solutions that you have never expected to exist. :-)

Regards,

Yi

From: TRNSYS-users [mailto:trnsys-users-bounces@lists.onebuilding.org] On Behalf Of Free

Sent: 14 April 2016 09:38

To: trnsys-users

Subject: Re: [TRNSYS-users] (PLEASE)optimization of a solar heating system combined with dual-source heatpump

Dear Yi, Jeff, Marko

Sincerely thank you for your answers!

The PSO in GenOpt is a Single - objective algorithm,i have tried to set the object function as the sum of energy consumption in a year or the life circle cost of the system, and the result coincided with Jeff's reply exactly. I will try a parametric analysis for system to find the problem as well.

Here is another question for Jeff:

<We'll use the Hooke-Jeeves algorithm on the tank volume and array area to get us in the right ballpark (with slope = latitude and south facing collectors at standard flow rates)>

I am eager to realize the object function and the criterion that you used for optimization,can you give me some suggestions for the unfavorable situation i struggled in?

Sorry to bother you again.

Ware

BR